'Wood You Believe It?' FAU Engineers Fortify Wood with Nano-Iron

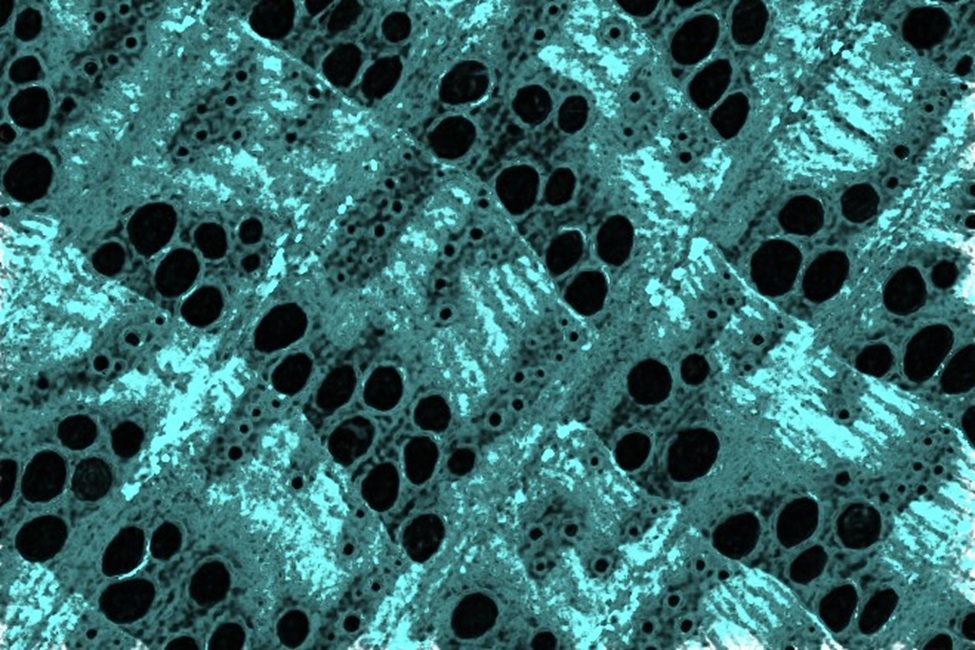

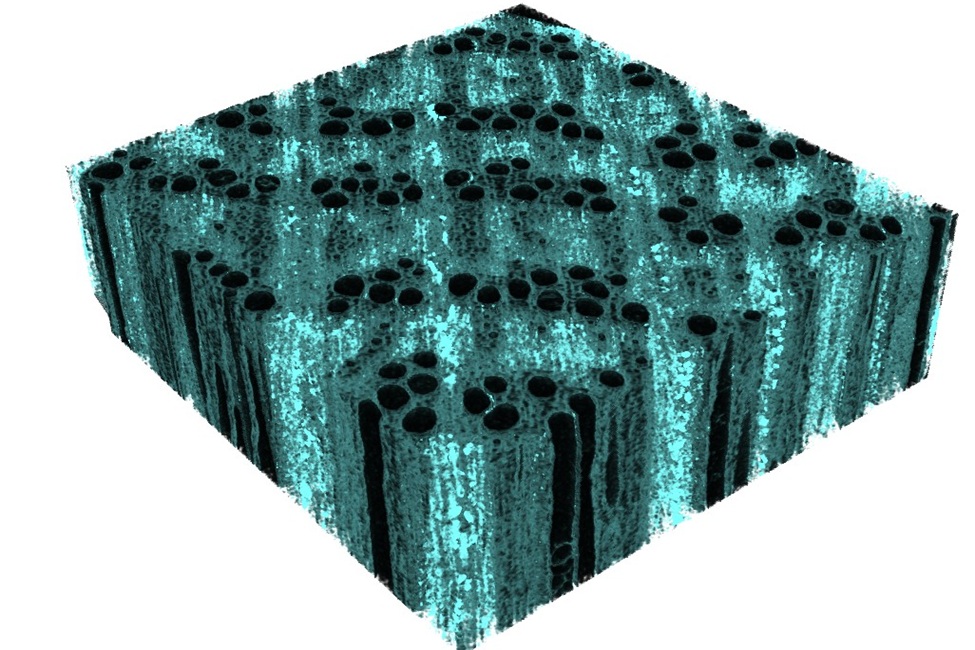

A microCT image shows the distribution of the iron mineral in the wood cell wall (in turquoise).

Scientists and engineers are developing high-performance materials from eco-friendly sources like plant waste. A key component, lignocellulose – found in wood and many plants – can be easily collected and chemically modified to improve its properties.

By using these kinds of chemical changes, researchers are creating advanced materials and new ways to design and build sustainably. With about 181.5 billion tons of wood produced globally each year, it’s one of the largest renewable material sources.

Researchers from the College of Engineering and Computer Science at Florida Atlantic University, and collaborators from the University of Miami and Oak Ridge National Laboratory, wanted to find out if adding extremely hard minerals at the nanoscale could make the walls of wood cells stronger – without making the wood heavy, expensive or bad for the environment. Few studies have investigated how treated wood performs at different scales, and none have successfully strengthened entire pieces of wood by incorporating inorganic minerals directly into the cell walls.

The research team focused on a special type of hardwood known as ring-porous wood, which comes from broad-leaf trees like oak, maple, cherry and walnut. These trees feature large, ring-shaped vessels in the wood that transport water from the roots to the leaves. For the study, researchers used red oak, a common hardwood in North America, and introduced an iron compound into the wood through a simple chemical reaction. By mixing ferric nitrate with potassium hydroxide, they created ferrihydrite, an iron oxide mineral commonly found in soil and water.

Results of the study, published in the journal ACS Applied Materials and Interfaces, revealed that a simple, cost-effective chemical method using a safe mineral called nanocrystalline iron oxyhydroxide can strengthen the tiny cell walls within wood while adding only a small amount of extra weight. Although the internal structure became more durable, the wood’s overall behavior – such as how it bends or breaks – remained largely unchanged. This is likely because the treatment weakened the connections between individual wood cells, affecting how the material holds together on a larger scale.

The findings suggest that, with the right chemical treatment, it’s possible to enhance the strength of wood and other plant-based materials without increasing their weight or harming the environment. These bio-based materials could one day replace traditional construction materials like steel and concrete in applications such as tall buildings, bridges, furniture and flooring.

“Wood, like many natural materials, has a complex structure with different layers and features at varying scales. To truly understand how wood bears loads and eventually fails, it’s essential to examine it across these different levels,” said Vivian Merk, Ph.D., senior author and an assistant professor in the FAU Department of Ocean and Mechanical Engineering, the FAU Department of Biomedical Engineering, and the FAU Department of Chemistry and Biochemistry within the Charles E. Schmidt College of Science. “To test our hypothesis – that adding tiny mineral crystals to the cell walls would strengthen them – we employed several types of mechanical testing at both the nanoscale and the macroscopic scale.”

For the study, researchers used advanced tools like atomic force microscopy (AFM) to examine the wood at a very small scale, allowing them to measure properties such as stiffness and elasticity. Specifically, they employed a technique called AM-FM (Amplitude Modulation – Frequency Modulation), which vibrates the AFM tip at two different frequencies. One frequency generates detailed surface images, while the other measures the material’s elasticity and stickiness. This method gave them a precise view of how the wood’s cell walls were altered after being treated with minerals.

Additionally, the team conducted nanoindentation tests within a scanning electron microscope (SEM), where tiny probes were pressed into the wood to measure its response to force in different areas. To round out their analysis, they performed standard mechanical tests – such as bending both untreated and treated wood samples – to evaluate their overall strength and how they broke under stress.

“By looking at wood at different levels – from the microscopic structures inside the cell walls all the way up to the full piece of wood – we were able to learn more about how to chemically improve natural materials for real-world use,” said Merk.

This combination of small- and large-scale testing helped the researchers understand how the treatment affected both the fine details inside the cell walls and the overall strength of the wood.

“This research marks a significant advancement in sustainable materials science and a meaningful stride toward eco-friendly construction and design,” said Stella Batalama, Ph.D., the dean of the College of Engineering and Computer Science. “By reinforcing natural wood through environmentally conscious and cost-effective methods, our researchers are laying the groundwork for a new generation of bio-based materials that have the potential to replace traditional materials like steel and concrete in structural applications. The impact of this work reaches far beyond the field of engineering – it contributes to global efforts to reduce carbon emissions, cut down on waste, and embrace sustainable, nature-inspired solutions for everything from buildings to large-scale infrastructure.”

Study co-authors are Steven A. Soini, a Ph.D. graduate from the FAU College of Engineering and Computer Science and FAU Charles E. Schmidt College of Science; Inam Lalani, a Ph.D. student at the University of Miami; Matthew L. Maron, Ph.D., a doctoral researcher at the University of Miami; David Gonzalez, a graduate student in the FAU College of Engineering and Computer Science; Hassan Mahfuz, Ph.D., a professor in the FAU Department of Ocean and Mechanical Engineering; and Neus Domingo-Marimon, Ph.D., senior R&D staff scientist, group leader for the Functional Atomic Force Microscopy Group, Oak Ridge National Laboratory.

A microCT image shows the distribution of the iron mineral in the wood cell wall (in turquoise).

-FAU-